Millions of views and counting: How a young Uzbek engineer’s YouTube videos went viral

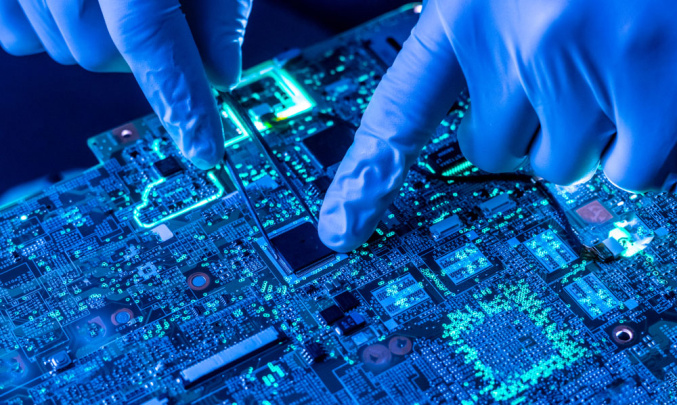

Jahongirmirzo Ibrohimov, a graduate of Inha University, shares his engineering projects created using a 3D printer on his YouTube channel in English. His videos, particularly in the platform’s Shorts (short-form video) section, garner millions of views. What began as a solo endeavor has now grown into a full-fledged team effort.

Hailing from Qoshtepa district in Fergana region, Jahongirmirzo leads a team that uses 3D printing to create modern, practical items and tools, making life easier for many.

“I am currently working as an engineer in Margilan city,” he says. “Based on my field, I post engineering-related videos on YouTube in both English and Uzbek. Our English-language channel is called Engineericly.

Most of our viewers come from English-speaking countries. On our English channel, you can see a variety of experiments. One example is an experiment tailored to Uzbekistan’s conditions called the Gravity Battery. The concept is simple: a heavy load is lifted to a height and then allowed to descend using gravity. As it descends, the load is connected to a generator, which rotates to produce energy. We installed solar panels on our house’s roof, and using the energy from those panels, we lifted heavy stones with a motor. After sunset, as the heavy loads descend, the generator rotates, producing electricity that we can use in the evening. We designed a small-scale concept of this idea and showcased it in a video. This video was well-received by our English-speaking audience, with over 500,000 views.

Our next project was the Sand Battery, another energy-related video. This experiment utilized the chemical properties of sand, which retains heat exceptionally well. Using energy from solar panels, we heated sand during the summer or daytime. The heat stored in the sand can then be used in winter to heat water, which in turn can heat homes. We demonstrated this concept in a video.

We also created a basketball using a 3D printer. Previously, Wilson released a similar product called the Airless Basketball, priced at $2,500. For a basketball, $2,500 is an exorbitant amount. So, we decided to create a more affordable version using our 3D printer. We made a video about this ball, which was viewed by nearly 20 million people on YouTube Shorts. Fun fact: our 3D printer worked non-stop for almost three days to produce that ball. Thankfully, the power didn’t go out during that time.

In addition to these experiments, we’ve also designed products and started selling them. One recent project is called the Gravity Hook. This, too, was liked and viewed by nearly 20 million people, and many requested that we sell the actual 3D-printed version. We haven’t started selling it yet, but, God willing, we’re on the verge of doing so. We aim to produce and export it from Uzbekistan to the world. For now, we’ve been selling the digital versions of our designs to people abroad who own 3D printers.

Another interesting series of experiments we do is called 3D Printing Versus Real. In this series, we create items with a 3D printer that mimic products available in the market and then compare the two. We’ve made over 20 videos in this series, including comparisons of boomerangs, tennis balls, tennis rackets, and even a soccer ball, pitting the 3D-printed versions against their real counterparts. On average, our 3D Printing Versus Real experiments have been viewed by over 200 million people worldwide.

Initially, we started producing our videos in English. After people learned I’m Uzbek, I began receiving comments asking why I don’t speak in Uzbek, urging me to make videos in my native language as well. So, I started creating Uzbek-language videos under my own name.

For example, one of our early videos involved scanning my hand with a 3D scanner and printing an exact plastic replica using a 3D printer. We then placed it in our room as a decoration.

Another project of ours, as you can see, is a real human brain. In this video, I wanted to print an exact replica of my brain using a 3D printer. I went to an MRI scanner to scan my brain and used the data to create a 3D model. It was a fascinating experiment.

Beyond sitting in the office creating items and making videos, we’ve also taken our custom-made technologies outside and conducted experiments among people. For instance, on Independence Day, we used our creations to distribute small flags to share the spirit of independence. Kids were especially intrigued by the machines we built. Another example: during Ramadan, we used one of our machines to distribute water and dates for iftar. These projects were very exciting for young people. I believe such initiatives play a significant role in sparking children’s interest in engineering.

Using special goggles, we’ve also controlled machines remotely from a distance. People couldn’t see that we were controlling the machines from afar because it was an experiment, but the machines reacted in sync with people’s responses. It was truly amazing.

Beyond the projects we’ve completed, we haven’t slowed down. For example, one of our current projects is a robotic manipulator arm. It’s not finished yet, but we’re very close. The goal of this robotic arm is to increase efficiency in factories. Until now, such arms have only been imported from China. Now, we aim to build this robotic arm from scratch in Uzbekistan. One of the best aspects of engineering is that you can create anything you want.

Throughout my work, I’ve noticed that people with disabilities rely on prosthetic legs imported from abroad, which are extremely expensive and take a long time to acquire. In the near future, we plan to start producing prosthetic legs in Uzbekistan. They will be cheaper and easier to produce than those imported from abroad,” says the young engineer Jahongirmirzo Ibrohimov.

Related News

19:29 / 30.05.2025

YouTube monetization in Uzbekistan could generate up to $50 million: What’s holding it back?

13:39 / 30.01.2025

Gov't introduces tax benefits for manufacturers of high-tech products

17:36 / 21.12.2024

Kun.uz YouTube channel surpasses 3 million subscribers

16:27 / 01.08.2024